Susan Brownlie

Manager, Product Development | New Zealand

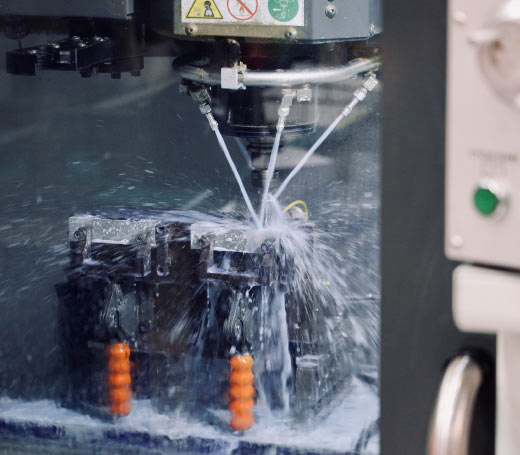

Allegion regularly invests in new machinery and technology, in addition to exploring methods to improve processes. The need for precision is of utmost importance and the accuracy of fixturing in the machines. All machines follow scheduled maintenance and servicing to maximise performance and efficiencies.

To consistently design and develop safety and security solutions, our local product and sales teams work closely together to proactively elicit customer feedback, conduct market research, and seek inspiration from current trends. We continue to monitor and test various aspects of the product throughout the manufacturing process. These may include tests to check the quality of springs, strength and durability, as well as surface finish and aesthetic checks, to ensure we maintain a high standard of quality.

To further set us apart in the market, Allegion New Zealand offers an extensive selection of special finishes produced in-house to complement architectural designs with our state-of-the-art electroplating plant.

Electroplated finishes add a premium appearance that gives the impression that the plated part is solid and of the same material as the finish. Allegion’s electroplating has automated high-throughput process that creates both consistency and highly durable finishing options. This helps ensure a faster turnaround, quality control, environmental respect, and the ability to accommodate special requests.

Donal Cronin

Operations Manager